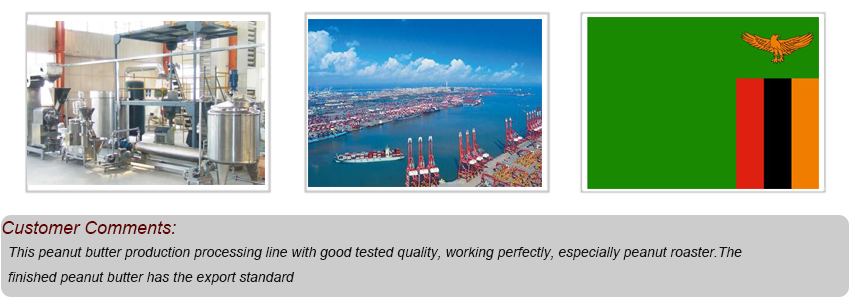

Continuous Peanut Butter Machine in Zambia

Katherine /

Katherine /  19 Sep,2016

19 Sep,2016

Peanut butter to high-quality peanuts and other raw materials processed into finished products for the hard and tough pulpy, rich fried peanut flavor. Quality peanut butter is generally light beige, fine quality, aroma, no impurities.

Depending on taste, peanut butter into sweet, salty two, is quite nutritious food adorned applied more widely in the Western. Generally divided into two kinds of smooth and coarse, coarse installed in making a good peanut butter then add the peanut granules, in order to increase its taste, while also added honey, chocolate, etc. made of different flavors, but not common.

How to Make Peanut Butter with Continuous Peanut Butter Production Line?

This peanut butter production processing line was designed by reference of the foreign tech. It is consisted of feed elevator, continuous roaster, conveyor, cooling machine, decorticating machine, sorting conveyor, grinding machines, pump, storage slot, cooling machine, mixing machine, vacuum deair, etc. It has advantages of high automation, easy-operating integrated control, stable performance, high product quality, etc.

The butter produced by this line can be 2-60um thickness, the homogeneous ratio can be above 95%. It is the ideal processing equipments to produce peanut butter, sesame soy, soybean paste, etc.

Instruction of peanut butter production line:

Roasting:

Batch roaster’s working temperature is 200-210 ºC, 20-30 minutes. Use batch roaster will bake some delicious smells.

Cooling:

Peanut will be send cooling belt to cool.

Peeling:

Put the roasted peanuts into peeler to take off the red skin, the double rollers will frication the red skin, the simple cyclone system will suck the red skins, most of them will be put in half-piece, then fall to the selecting conveyor, the over-roasted andun-blanched peanut kernel is picked up by manual or mechanical.

Primary grinding:

Using steel grinder to make the first grinding.

Second grinding:

Using colloid grinder to make the second grinding, the fineness of grinding is controlled below 7μm, temperature of grinding is controlled below 68C.

Mixing:

Make the butter more homogeneous.

Cooling:

The butter through second grinding should be cooled immediately. The temperature should go down 45C.

Degasser:

Take out the air from peanut butter.

Storage tank:

Settling down in the storage tank till the temperature drop to air temperature.