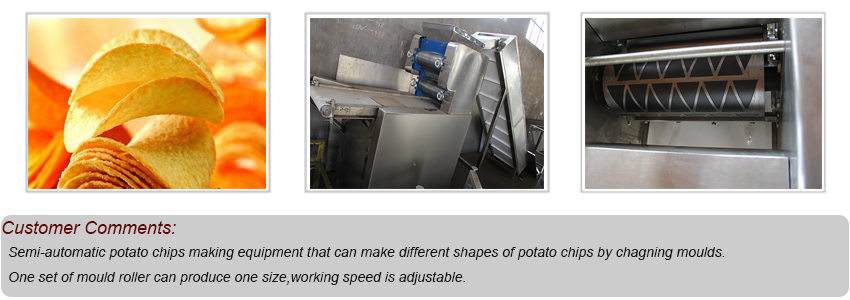

Semi-automatic Potato Chips Making Equipment in India

Katherine /

Katherine /  27 Feb,2016

27 Feb,2016

Potato chips production line, the main process is divided into: cleaning peeling → slice / silk scalding → dehydration → off the frying oil spices → cooling → packaging.

To obtain good quality of fried potato chips, reducing consumption of raw materials, process requirements must select composite potato. Therefore, the required raw materials for the tuber shape and tidy, relatively uniform size, consistent color table thin, small buds, relatively high density, high starch and total solids content, low sugar content, relatively uniform soil environment of potato cultivation.

For cuttting potato slices,hand sliced aleays uneven, generally used in automatic rotary blade slices. Slice thickness based on the tuber harvest season storage time depending on how much moisture content. Just harvested potato tubers full, high water content, the slice thickness control in 1.8 to 2.0 mm. Long storage time, moisture evaporation, high solids content tubers, slice thickness of 1.6 to 1.8 mm are preferred.To cut potato chips in the sink with wash water surface starch to prevent the pre-cooked starch pasting sticky sheet, the impact of deep-fried results.

In order to improve the flavor of fried potato chips, potato chips increase the appearance of color, increasing consumer appetite, color protection after the potato chips have to be coupled with 1% to 2% salt and processing a certain amount of pigment citric acid pool again soak for 10 to 20 minutes, the salt flavor and color to permeate the entire film, so salty fried potato chips after suitable, good appearance.

Salt and coloring will meet the technical requirements of the chips picked up from the pool, then pour off the dryer section of free water. Because too high frying potato chips surface moisture surface blistering, oil bubble inside, it will affect the appearance, but also increases fuel consumption, the higher the better dehydrated potato chips.