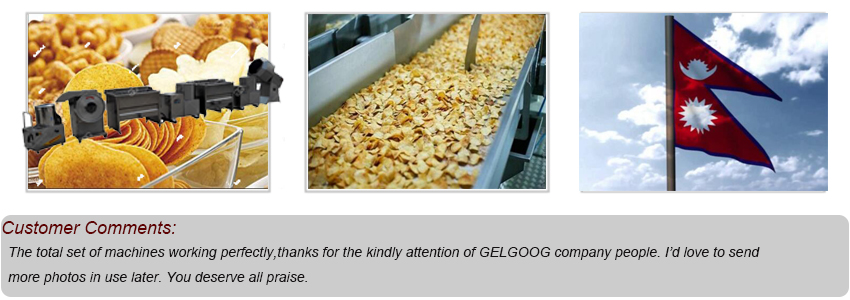

Nepal Customer For 60kg/h Semi-automatic Potato Chips Machines

Katherine /

Katherine /  19 Sep,2016

19 Sep,2016

Quantity: 1 set

Certificate: CE

Destination Port: Kolkatta

Destination Port: Kolkatta

Place: Nepal

Semi-automatic Potato Chips|French Fries Production Line is manufactured accroding to the demands of market. The first step is cleaning and peeling selected potatos. After cleaning the potato is fed to the steam peeler or mechanical peelers peeled. Then enter the second washer and the residue paste potato potato skin surface washed. After cleaning the potatoes, it is fed to the detection stage, to achieve manual sorting and finishing peeled potatoes.The belt conveyor is fed to the peeled potato slicer. Sliced potatoes are needed. And washed with water to free the starch.

Semi-automatic Potato Chips|French Fries Production Line is manufactured accroding to the demands of market. The first step is cleaning and peeling selected potatos. After cleaning the potato is fed to the steam peeler or mechanical peelers peeled. Then enter the second washer and the residue paste potato potato skin surface washed. After cleaning the potatoes, it is fed to the detection stage, to achieve manual sorting and finishing peeled potatoes.The belt conveyor is fed to the peeled potato slicer. Sliced potatoes are needed. And washed with water to free the starch.

After cleaning the chips are sent to blanching machine for blanching, washing and bleaching from hot chips carry out a large number of attachment of water. Shaker use with strong winds, the individual chips separated and attached to the water dry. Then conveyed to the fryer, the potato chips to reduce the moisture content from 80% to 2%, to give crispy products. Oil content in the finished fried crisps in between 30% -40%. Fried potato chips is transported to the conveyor belt and drain, drain the oil remaining on the surface of products. Fried potato chips are transported to the drum machine potato chips flavored seasoning, depending on the product add different seasonings. Flavored potato chips then can be transported to the packing plant, for packing into different shapes and sizes.