Steamed and air-fried Instant Noodles Processing Line Scheme

Katherine /

Katherine /  19 Sep,2016

19 Sep,2016

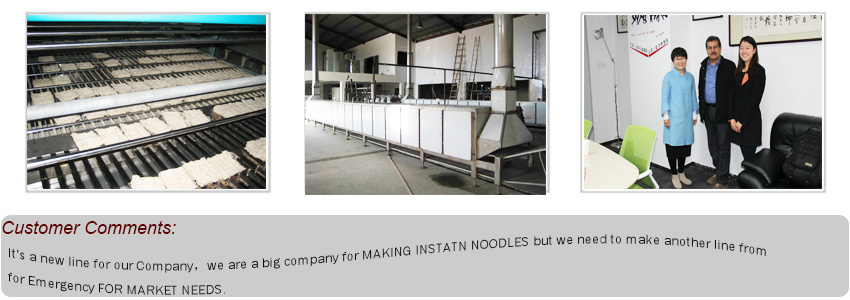

On April 5th, Indonesian client visited for Steamed and air-fried Instant Noodles Processing Line Scheme.

Automatic instant noodle processing line with perfect technology, compact structure, original design and stable perfomance. it realizes high automation, convenient operation, low energy consumption. All working procedures from feeding flour to finished products can be accomplished automatically.

By the drying process there are fried instant noodle machines (noodle lines) and hot air drying noodle lines. Hot air drying instant noodle machinery and instant production noodle lines, on the other hand, the noodles are dried in hot air at 70 ℃ -90 ℃ after cooking; instant noodles made by hot-air drying instant noodle machinery, are not easily oxidated and rancidity is avoid. Long shelf life and low cost can be guaranteed. However, due to its low drying temperature, low gelatinization, and poor internal porosity in noodles, the final product requires longer rehydration time.

Instant noodle machine manufactured by Gelgoog Company adopted new technology, equipment instead of fried and dried, and the bread good rehydration.For example, high-temperature hot air drying, microwave drying, drying and frying dried ordinary combination of the product oil lower, extend shelf life. With a new formula to improve texture and rehydration -You can add some, such as starch, alginic acid, propylene glycol and other additives. The production of high-nutrition instant noodles - Adding vitamins, lysine and the like wheat flour lack of substance, so that nutrition is more comprehensive and more abundant.

Instant noodle machine manufactured by Gelgoog Company adopted new technology, equipment instead of fried and dried, and the bread good rehydration.For example, high-temperature hot air drying, microwave drying, drying and frying dried ordinary combination of the product oil lower, extend shelf life. With a new formula to improve texture and rehydration -You can add some, such as starch, alginic acid, propylene glycol and other additives. The production of high-nutrition instant noodles - Adding vitamins, lysine and the like wheat flour lack of substance, so that nutrition is more comprehensive and more abundant.