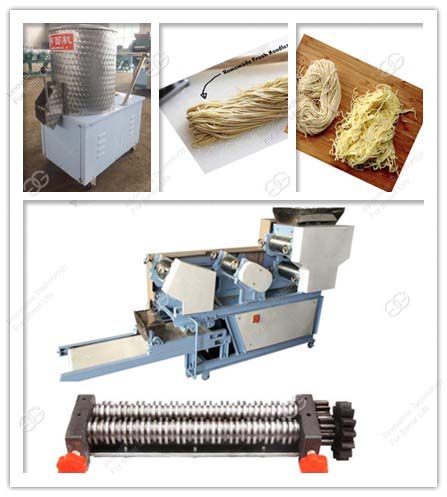

Fresh Noodle Making Machine With Dough Mixer in US

Katherine /

Katherine /  05 Aug,2016

05 Aug,2016

Fresh noodle machine sold in US. Customer is business of making fresh noodles, in urgent need of fresh noodle making machine with capacity 150kg/h.

Fresh noodle machine sold in US. Customer is business of making fresh noodles, in urgent need of fresh noodle making machine with capacity 150kg/h.The features of dough mixer:

1. All parts in contact with food are made of stainless steel which is endurable in use and in conformity with national food hygiene standard

2. The agitator is designed to do planetary motion inside the bowl where the food can be fully blent

3. Different capacity to meet your different requirement

4. Very easy to operate and maintain.

5.the flour and water is 4:1

The features of fresh noodle making machine:

New noodle making machine, a molding press or auto repeat function has, according to their needs, to facilitate user-friendly design, operation, high yield provincial labor, small power and energy saving, no noise is good security, easy to clean standard 304 stainless steel package and health, dusting how much the amount of any regulation, production speed arbitrary regulation, all components of the material is good and stable performance.

The features of fresh noodle making machine:

New noodle making machine, a molding press or auto repeat function has, according to their needs, to facilitate user-friendly design, operation, high yield provincial labor, small power and energy saving, no noise is good security, easy to clean standard 304 stainless steel package and health, dusting how much the amount of any regulation, production speed arbitrary regulation, all components of the material is good and stable performance.

As to the noodle molding knifes, we can customize the forming width of knifes according to customers’ exact demands; The knifes can be changed to get the noodles with different size easily when needed.

GGMT5-200 noodle making machine is with

Width of dough facets: 200mm

Size of main pressing roller:Ø96*250mm

Power: 3KW

Dimension: 1600*570*1220mm

Weight: 350kg

Instructions for using fresh noodle machine:

1. Before using the machine on a level ground, make sure the machine work smoothly and reliably.

2. Before the use of the inter-ministerial inspection of transmission parts inspection, turned by hand blender flexible; check whether the fasteners are loose in transit; switch and power cord is no transportation damage.

3. Check the existing mains voltage and rated voltage of this product is consistent.

4. The rubber power cord elongation, the yellow-green grounding wire reliably with earth symbol, the remaining three cores (with single-phase motors for two) respectively to open load switch (knife switch) OFF lead terminals open on time.

5. Closed open load switch, start switch handle, the machine running smoothly, there is no abnormal sound is before the test machine.

6. Operation: Before starting the machine, the agitated flour, additives and other materials added to the barrel, running one to two minutes, then add the right amount of water, can also be added to the first barrel of flour, water and then thoroughly mixed with additives Join cylinder, rear view uniform mixing of materials, the material containing the appliance is placed below the discharge port, lift the striker plate, stir the material can be automatically excluded, fall within the appliance containing material