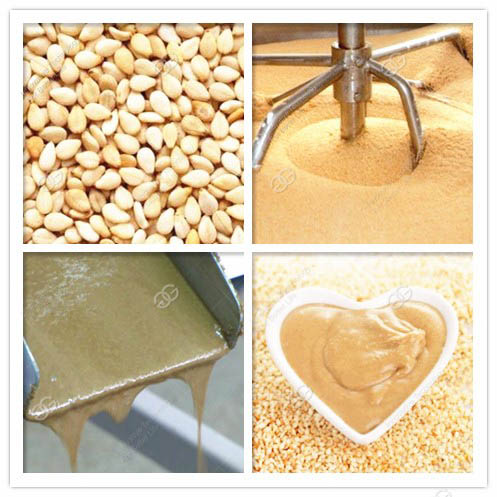

Mechanized Production Line of Sesame Tahini

Katherine /

Katherine /  30 Mar,2017

30 Mar,2017

Sesame seeds are soaked in water at a temperature of 50°C for between 0.5 - 3 hours using 100 - 1500 litres of water. The process of separation is a continuous process where the seeds including the core and the shell are placed in a saline solution with a density of 1120 - 1150 kg/m3. Due to the different densities the seed core floats whilst the heavier shell is deposited at the bottom of the solution.

Centrifugal and heat treatments are used in the drying and separation process to further enhance the taste, aroma and colour qualities.

The temperature of the coolant depends on the design of the apparatus used for frying, and ranges between 150-300* C.

The total set of Sesame Tahini Production Line consists of feed elevator, continuous cleaner and dryer machine, continuous roaster, cooling machine, storing and feeding machine, grinding machines, mixing machine, vacuum degassing tank, pump and other spare parts. It has advantages of high automation, easy-operating, integrated control, stable performance, high product quality etc.

The total set of Sesame Tahini Production Line consists of feed elevator, continuous cleaner and dryer machine, continuous roaster, cooling machine, storing and feeding machine, grinding machines, mixing machine, vacuum degassing tank, pump and other spare parts. It has advantages of high automation, easy-operating, integrated control, stable performance, high product quality etc.

The production process of Sesame Tahini:

Sesame cleaning → Drying → Roasting → Cooling → Grinding→ Packing → Finished

Production process control:

1. Cleaning

Using sesame cleaning machine to clean the raw material, removal of dust adhered on sesame and sesame small shriveled grain, remove with a strainer into the basket, the water dry control.

2.Drying: Drying the sesame after cleaning.

2.Drying: Drying the sesame after cleaning.

3. Roasting: Sesame wash dry control water was put into a furnace for stir fry, fry sub temperature 150 ℃, time of 50min point

The roasted sesame removed from the oven when removing the raised shovel to remove the sub-fried sesame mixed with soot process.

6. Cooling down after the sesame seeds into special cooling pool for cooling, cooling to 25 ℃

7. Grinding

Cooling good sesame seeds into the stone polishing, stone speed of 45 rpm / min, grinding time of 100kg / 60min, until the sesame fineness of 80 mesh so far.

8. Filling: bottles before entering the packing room for disinfection, strict control of the net content when canned.

9. Product testing:Workshop package including inspectors randomly selected sample, tested in accordance with the product standards. Original records and do an inspection report.

10. Packing: It passed the test of the product into the outsourcing packaging workshop, external bag and carton production date, net content labeling and the name of the test.

Packing Storage:

1. Processed products between Bulk packaging, packing room with a UV light disinfection facilities.

1. Processed products between Bulk packaging, packing room with a UV light disinfection facilities.

2. Treasury regularly disinfected, warehouse control temperature and relative humidity.

3. Proprietary food product transport vehicles.