Potato Crisps Plant

Katherine /

Katherine /  01 Apr,2016

01 Apr,2016

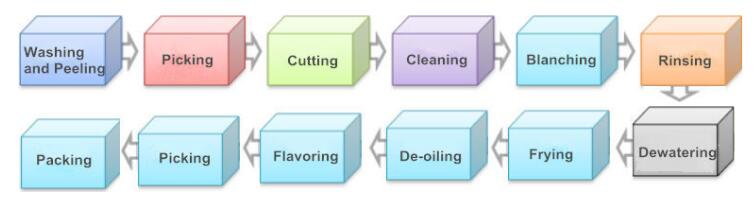

How does a potato turn into potato chips or potato crisps basically rely on potato crisps plant. The popularity of potato chips quickly spread across the country, particularly in speakeasies, spawning a flurry of home-based companies. According to snack food folklore, the potato chip was invented in 1853 by a chef named George Crum at a restaurant called Moon's Lake House in Saratoga Spring, New York.

When the potatoes arrive at the plant, they are examined and tasted for quality. A half dozen or so buckets are randomly filled. Some are punched with holes in their cores so that they can be tracked through the cooking process. The potatoes are examined for green edges and blemishes. The pile of defective potatoes is weighed; if the weight exceeds a company's preset allowance, the entire truckload can be rejected.

Taste samples are made from each batch throughout the manufacturing process, usually at a rate of once per hour. The tasters check the chips for salt, seasoning, moisture, color, and overall flavor. Color is compared to charts that show acceptable chip colors.

Preventing breakage is a primary goal for potato crisps manufacturers. Companies have installed safeguards at various points in the manufacturing process to decrease the chances for breakage. The heights that chips fall from conveyer belts to fryers have been decreased. Plastic conveyer belts have been replaced with wide mesh stainless steel belts. These allow only the larger chips to travel to the fryers and the smaller potato slivers to fall through the mesh.

Gelgoog Machinery is one of the top Potato Crisps Plant in China suppliers. Gelgoog offers automatic potato chips line and semi-automatic potato chips or crisps line.

Gelgoog Machinery is one of the top Potato Crisps Plant in China suppliers. Gelgoog offers automatic potato chips line and semi-automatic potato chips or crisps line.