Features

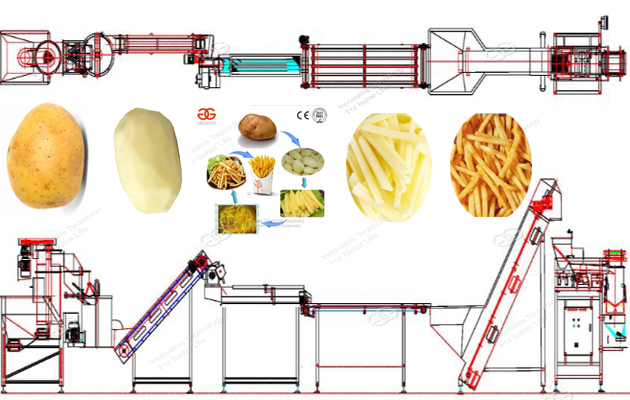

Features: This automatic french fries production line is fully automatic from feeding material to finished french fries. GELGOOG also offer Small Scale French Fries Production Line

Pre-Washing Peeling Machine: This elevator will take the potato to pre washing machine to wash and remove the mud on the surface.

Sorting Conveyor: After potato peeled, the potato will come into the sorting conveyor. Then can sort the unqualified potato,potato is not peeled well.

Potato Fries Cutter: After sorted well, qualified potatoes will be put into the cutting machine. It can cut continuous.

Impurity Removing Machine: After the potato chips finished cutting, elevator will send potato chips to the Impurity Removing Machine.

Rinsing Machine: After the potato chips coming from the Impurity Removing Machine, the qualified potato chips will drop the Rinsing machine directly.

Blanching Machine: After rinsed, potato chips will coming into blanching machine, this blanching machine is adopts with electricity heating.

Air De-watering Machine: After Vibrating dewatering machine, the potato chips will coming into the air de-watering machine, thus the water will remove completely.

Fryer machine: This machine is made of pure oil process technology, it is with dynamic filting system, it can filt and discharge the residue automatically to make sure the qulity of the oil.

Technical Data

| Item | Parameter |

| 1. Pre-washing Elevator | Power: 750W, Dimension:1800*1200*1500mm |

| 2. Pre-Washing Machine | Power:5.1KW, Dimension:3000*900*1400mm |

| 3.Elevator | Power:750W, 380V/50HZ, Dimension: 2000*1000*1600mm |

| 4.Emery Peeling Machine | Frame all with 50*50*2mm, superior Stainless Steel 304 tube, bearing is made of Stainless Steel 316 Bearings. |

| 5.Sorting Conveyor | Power;0.75KW,380V, 50HZ |

| 6.Waste Transfer Cart | All made of Stainless Steel 304. Dimension: 600*500*400 |

| 7. Potato Chips Cutting Machine(Two Sets) | Dimension: 900*850*900mm Power:1.1kw Weight:120kg |

| 8.Elevator | |

| 9.Impurity Removing Machine | Dimension:2600*1000*1400mm Power:1.5KW, Weight:380KG |

| 10.Rinsing Machine | Dimension:6000*1600*1400mm Power:3.7KW,380V,50HZ |

| 11. Blanching Machine | All material are made of stainless steel 304, Width of 800mm, mesh with size of 3mm. |

| 12. Vibrating De-watering Machine | Dimension:1800*1500*1300mm |

| 13.Air De-watering Machine | Dimension:8000*1600*1600mm Power:15KW,380V,50HZ,Three-phase. |

| 14. Stainless Steel Elevator | Power:750W,380V,50HZ Dimension:2000*1500*1350mm |

| 15.Fryer Machine | Dimension:8000*1600*2400mm |

| 16.Oil Filting Machine | Then the oil will be send to fine filter by pump. |

| 17.Oil Adding Tank | Oil Adding Tank is with heating device. |

| 18. Vibrating Oil-Removing Machine | Frame made of 100*50*5mm, vibrating motor of 0.25kw |

| 19.Air De-oil Line | Dimension: 8000x1600x1600mm Power:15kw/ 380V/50Hz 3 phase |

| 20. Elevator | Power: 0.75KW/380V/50HZ Dimension:2000*100081600mm |

| 21. Distributing Machine | Frame tubes are with 100*50*5mm, superior SS304, vibrating motor 0.25kw |

| 22. Frozen Tunnel | Power: 300kw/380v/50hz Dimension: 20000*3000*3000mm |

| 23.Automaic Packing Machine | Dimension: 3000*2000*2600mm |